What to Focus on to Improve Your Core Business Processes

As the economy bounces between growth and recession, organizations are challenged with adding and/or reducing staff on almost a monthly basis. This pressure to reduce operational costs and at the same-time grow revenues requires a review of core business processes.

Companies are looking at how to streamline and/or eliminate non-value-added steps in those critical business processes that impact EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization). Continuous performance and improvement never goes out of style, but should be focused on the following:

1. Sales and Operations Planning (S&OP)

S&OP is a business and management process used to develop a unified plan for meeting customer demand by aligning sales, marketing, finance, and operational processes.

The following functional areas need to be part of the process:

- Demand Planning: This helps to forecast demand for products so that an organization can ensure they deliver what is needed of them. This is important in helping keep customers satisfied.

- Supply Planning: After seeing the forecasted demand, an organization needs to make sure they have the required supply to meet that demand. Supply planning aligns the materials and production that is needed to do this.

- Production Planning (if a manufacturing entity): Production planning is a process that goes into depth about how a company will manufacture their product/services. If you’re a manufacturing company, production planning can lower production costs, increase customer satisfaction, improve efficiency, etc.

- Purchasing: Purchasing is when a company buys the necessary goods and services to reach their demand and supply goals. With a proper purchasing strategy, an organization can lower costs, reduce risk of supply shortage, and increase innovation among products/services.

- Inventory Planning and Management: This functional area is all about aligning the number of product/services an organization should have in stock with the overall sales goals and customer demand. Factors that go into this is shipping costs, storage costs, inventory turnover rate, etc.

Creating and utilizing a robust and sustainable process ensures that assets are effectively utilized to meet demand while minimizing costs and maximizing profitability. In addition, the leader of the sales and operations process must require each participant from the functional groups listed to consistently participate and communicate with the required data to have success. This process must exist for each of the major product lines.

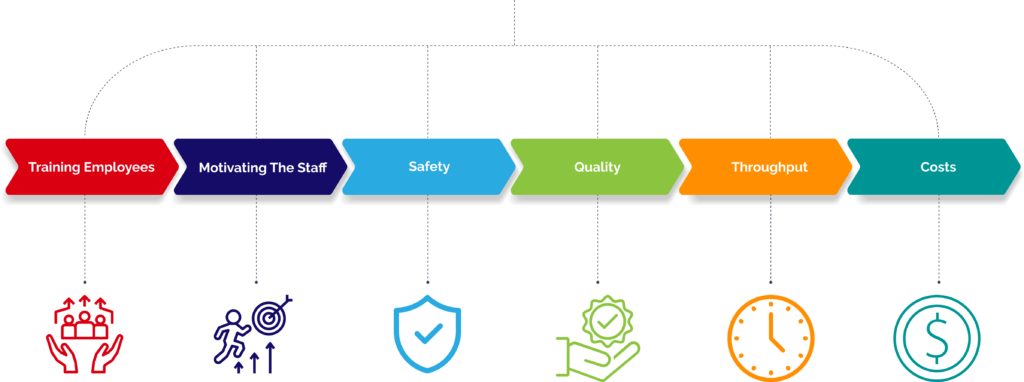

2. Key Performance Indicators (KPI’s)

- Training Employees: This ensures that the employee is qualified to perform the task and has the knowledge required. Business processes, procedures, computer systems, and equipment change over time. Tracking those types of metrics also supports the promotion process.

- Motivating the Staff: Listening and providing feedback (positive or negative) demonstrates to the employees that you care about them. Obtaining employee input regarding processes and procedures will likely improve process performance.

- Safety: Obtain insights from the employees on potential hazards so corrective actions can be implemented. Accidents can lead to increased insurance premiums and costly fines.

- Quality: Identifying the root cause of quality issues lower costs and improves margins.

- Throughput: Whether your organization produces items or distributes products, tracking throughput time saves time and money.

- Costs: Tracking metrics such as overtime, expedited shipping costs, purchased item costs, inbound freight costs, etc. assists the organization in identifying where time needs to be spent on root cause analysis.

Tracking core business processes should be part of the culture and philosophy of a business regardless of your industry. Focusing on improving those core business processes will generate the most value for the company and your customers.